See New Conference Content

See New Conference Content

Search the world's largest collection of optics and photonics applied research.

Announcements

REVIEWER TRAINING PROGRAM

Become a great peer reviewer! This essential peer review training course offers a blend of online learning and hands-on peer review experience.

Get Started with the Reviewer Training Program

ENGLISH LANGUAGE EDITING SERVICES

SPIE partners with Editage to offer English language editing services to researchers worldwide.

15% discount applied at checkout

TECHNOLOGIES

The most viewed articles by technology, from SPIE Journals and Proceedings

Origins Space Telescope: baseline mission concept

J. Astronomical Telescopes, Instruments, and Systems (2021)

The Copernicus CO2M mission for monitoring anthropogenic carbon dioxide emissions from space

Proceedings of SPIE (2021)

Identification of different types of tumors based on photoacoustic spectral analysis: preclinical feasibility studies on skin tumors

J. of Biomedical Optics (2023)

Kernel Flux: a whole-head 432-magnetometer optically-pumped magnetoencephalography (OP-MEG) system for brain activity imaging during natural human experiences

Proceedings of SPIE (2021)

High capacity and access rate, data storage using laser communications

Optical Engineering (2021)

Modular FSO Optical System Design for Classical and Quantum Optical Communication Systems

Proceedings of SPIE (2021)

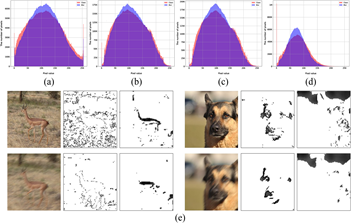

Survey on deep learning applications in digital image security

Optical Engineering (2021)

Tactical agility for AI-enabled multi-domain operations

Proceedings of SPIE (2023)

Efficient detection of crossing pedestrians from a moving vehicle with an array of cameras

Optical Engineering (2022)

Research on bridge defect detection technology based on image processing technology

Proceedings of SPIE (2023)

Holographic low concentration optical system increasing light collection efficiency of regular solar panels

J. Photonics for Energy (2021)

GALACTIC: high performance alexandrite crystals and coatings for high power space applications

Proceedings of SPIE (2021)

Structured light for ultrafast laser micro- and nanoprocessing

Optical Engineering (2021)

Development of LISA laser system at NASA

Proceedings of SPIE (2023)

Speckle control for electro-holographic display using high-brightness yellow phosphor light source in projector

Optical Engineering (2023)

Modular FSO Optical System Design for Classical and Quantum Optical Communication Systems

Proceedings of SPIE (2021)

Potential of E-beam lithography for micro- and nano-optics fabrication on large areas

J. Micro/Nanolithography, MEMS, and MOEMS (2023)

High-NA EUV Lithography exposure tool: advantages and program progress

Proceedings of SPIE (2021)

Enabling precision coordinate metrology for universal optical testing and alignment applications

Optical Engineering (2021)

Novel diffraction-based overlay metrology utilizing phase-based overlay for improved robustness

Proceedings of SPIE (2021)

Graphene/molybdenum disulfide nanocomposites: characterization and optoelectronic application

J. Nanophotonics (2023)

Carbon nanotube EUV pellicle tunability and lifetime

Proceedings of SPIE (2021)

Opto-thermo-mechanical phenomena in satellite free-space optical communications: survey and challenges

Optical Engineering (2023)

Optical communication requirements for scientific missions and the Deep Space Gateway

Proceedings of SPIE (2023)

Satellite remote sensing of river discharge: a framework for assessing the accuracy of discharge estimates made from satellite remote sensing observations

J. Applied Remote Sensing (2023)

A synchronized remote sensing monitoring approach in the Livingstone island region of Antarctica

Proceedings of SPIE (2023)

Technical concepts of automotive LiDAR sensors: a review

Optical Engineering (2023)

New developments of multilinear and multispectral infrared sensors for space applications at LYNRED

Proceedings of SPIE (2023)